Cummins and Perkins Generators Remain the Trusted Choice for Reliable Power Solutions Worldwide

Release time:2025-10-09 Click:14

Cummins and Perkins Generators Remain the Trusted Choice for Reliable Power

For decades Cummins and Perkins have been synonymous with dependable power across the globe. From data centers and hospitals to construction sites and remote microgrids these two engine-makers deliver generator sets that combine mechanical robustness with modern control systems. Reliability matters more than ever as businesses, municipalities and critical facilities depend on continuous electricity to protect people assets and revenue. This article explores why Cummins and Perkins remain preferred brands how they compare what technical advantages they offer and answers common questions buyers and operators ask when selecting a generator solution.

A legacy of engineering and global support

Cummins founded in 1919 and Perkins established in 1932 each built a long history of engine innovation. Cummins gained recognition for heavy duty diesel engines high power density and extensive industrial applications. Perkins earned its reputation through compact reliable medium duty engines that are easy to service. Beyond the engines both companies invested early in distributor networks parts logistics and technical training. That global support footprint means spare parts and certified technicians are often available near installation sites reducing downtime and making lifecycle ownership predictable.

Why reliability still wins

Reliable power is the primary selection factor for mission critical operations. An unexpected outage can halt production damage equipment or risk lives. Cummins and Perkins designs emphasize robust components proven cooling systems and conservative thermal management. Combined with advanced control units these generator sets start quickly stabilize voltage and frequency and handle abrupt load changes. Reliability is further enhanced by proven manufacturing processes long term field testing and continuous improvement programs that feed lessons learned back into new product releases.

Product ranges and target applications

Cummins typically targets high power industrial use cases offering generators from small kilovoltampere units to large multi megawatt installations ideal for data centers hospitals heavy industry and mining. Perkins focuses on small to mid size applications including agricultural equipment construction light commercial backup and modular power units. Together these ranges cover virtually every customer need from portable standby power to prime continuous supply.

Control systems remote monitoring and smart features

Modern generator systems are more than just engines and alternators. Cummins PowerCommand and Perkins electronic control modules provide digital control protective functions synchronising capabilities and remote telemetry. These control platforms enable automatic start/stop load sharing fault diagnostics and IoT integration for predictive maintenance. Remote monitoring reduces unnecessary site visits and enables technicians to diagnose issues before failure occurs improving uptime and lowering operational costs.

Efficiency emissions and compliance with global standards

Both manufacturers have invested heavily in emissions control and fuel efficiency. Cummins and Perkins engines meet stringent global standards such as EPA Tier 4 and EU Stage V through optimized fuel injection turbocharging and after treatment systems. These improvements reduce NOx particulates and overall CO2 intensity per kWh produced making modern diesel or gas generator sets much cleaner. For customers seeking greener solutions both companies offer hybrid configurations bi fuel options and compatibility with biodiesel or natural gas in many models.

Total cost of ownership and lifecycle value

Initial purchase price is only part of the decision. Total cost of ownership includes fuel consumption maintenance parts downtime risk and resale value. Cummins and Perkins engines are designed for long service intervals and high mean time between failures which lowers maintenance frequency. Global parts availability and factory backed service plans reduce repair lead times. In many cases a higher quality generator pays back through lower lifetime costs and reduced business interruption exposure.

Integration with renewable energy and hybrid systems

As customers adopt solar battery and hybrid microgrid solutions Cummins and Perkins have adapted by offering generator sets that operate seamlessly with renewable sources. Smart controllers can manage charge assist modes perform black start capability and dispatch gensets only when necessary to optimize fuel use and reduce emissions. These integrated solutions deliver the reliability of conventional backup with the efficiency advantages of renewables.

Common questions and answers about Cummins and Perkins generators

Q: Which brand should I choose Cummins or Perkins

A: Choice depends on application scale and local support. Cummins is often selected for very large industrial or continuous duty applications. Perkins is widely chosen for medium duty and situations where compact footprint simple servicing and cost efficiency are priorities. Both brands are highly reliable.

Q: How available are spare parts and service globally

A: Both companies maintain extensive dealer and distributor networks. Genuine parts and certified technicians are available in most regions which shortens repair times and simplifies routine maintenance.

Q: Can these generators be remotely monitored

A: Yes. Cummins offers Connected Solutions and Perkins supports remote telemetry enabling performance dashboards fault alerts and predictive maintenance workflows. Remote monitoring is standard practice for modern installations.

Q: Are there low emission or alternative fuel options

A: Yes. Many models accept biodiesel blends natural gas conversions or come with advanced aftertreatment to meet strict emissions rules. Hybrid systems combining battery and genset are also available.

Applications where reliability matters most

Critical environments such as hospitals data centers airports telecommunications and emergency response centers require instantaneous and unwavering power. Cummins and Perkins gensets are commonly selected because they offer tested start reliability stable frequency regulation and quick transfer capabilities needed to protect sensitive equipment and human safety.

Maintenance best practices and operator training

To get the best performance schedule periodic inspections change filters and oil maintain cooling systems and follow manufacturer recommended load tests. Operator and technician training supplied by authorized dealers reduces user error and ensures that preventive maintenance is properly performed extending engine life and preserving warranties.

Real world case examples

In manufacturing plants Cummins generator sets have provided multi season continuous backup enabling production continuity during grid instability. In rural electrification projects Perkins powered units have reliably supported water pumping refrigeration and small scale processing where grid extension is not feasible. These success stories highlight how choice of engine and service model influence long term outcomes.

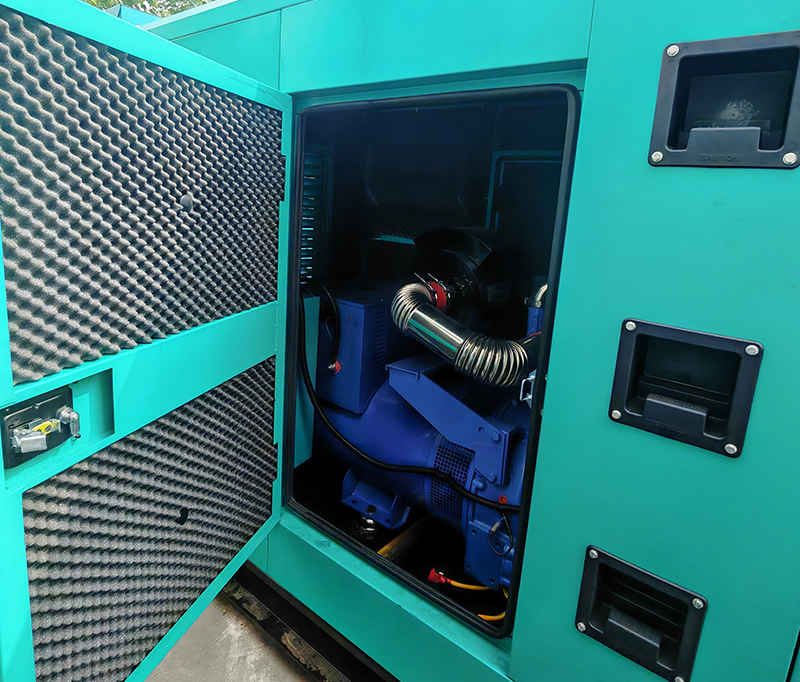

Selecting the right model matching capacity and duty profile

Specifying the correct genset involves understanding prime versus standby duty calculating typical and peak loads specifying ambient conditions and considering altitude and fuel quality. Authorized dealers from both Cummins and Perkins can perform site surveys and load studies to recommend appropriately rated gensets and accessory packages including sound attenuation and paralleling switchgear.

Future directions and innovations

Both manufacturers continue developing cleaner more connected and more flexible power solutions. Advances include higher efficiency combustion systems wider hybrid compatibility hydrogen ready platforms and expanded IoT capabilities for fleet scale optimization. These innovations ensure Cummins and Perkins remain relevant as energy systems become more distributed and decarbonized.

Conclusion

Cummins and Perkins generators remain top choices for organizations that require dependable power. Their deep engineering heritage global service networks and continuous product evolution deliver the reliability efficiency and lifecycle value that critical infrastructure and commercial operations demand. Whether the requirement is heavy industrial prime power or compact reliable standby capacity these two brands continue to provide solutions that keep systems running and businesses protected.

Hot products

+86 15244567972

Contacts:Jack