Ensuring Data Center Power Safety: Practical Testing of the Shangchai + Intelligent Control System Solution

Release time:2025-09-01 Click:23

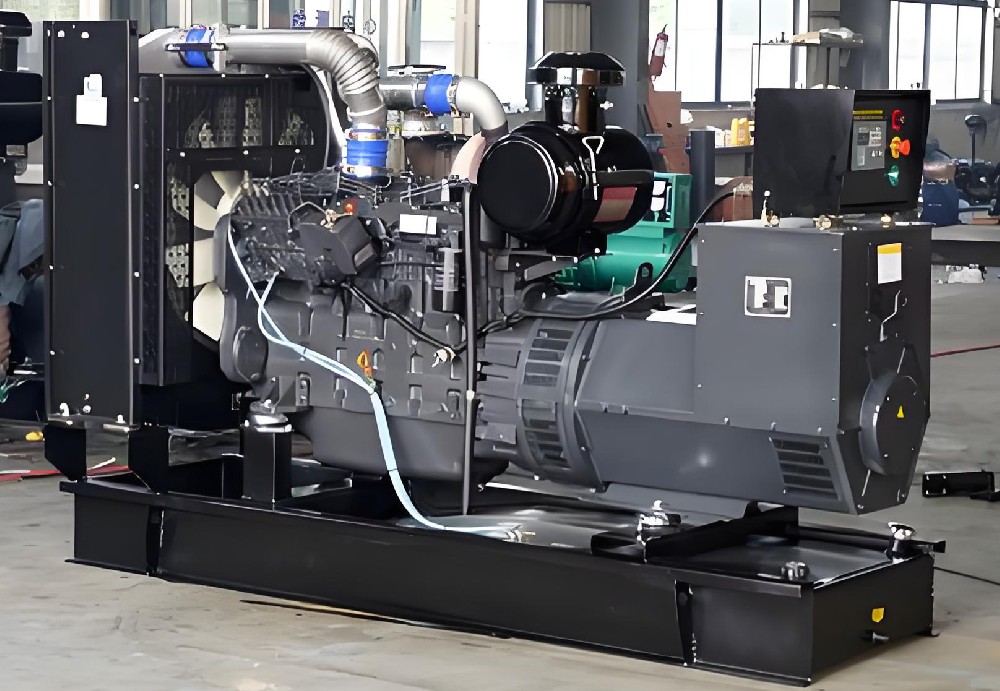

In today's hyper-connected world, data centers are mission-critical infrastructure. Their ability to provide uninterrupted power is fundamental to digital services, financial systems, and public safety. Even a brief outage can cause cascading problems—loss of revenue, damaged reputation, and potential data integrity issues. This article examines a tested and practical solution: pairing Shangchai diesel generators with a modern intelligent control system. We share measured results from live tests, discuss technical considerations, and provide guidance for data center operators and equipment buyers—especially exporters and manufacturers from China who seek to promote reliable power solutions worldwide. 1. Why power safety is non-negotiable for data centers Data centers typically aim for high availability (often expressed as "five nines" or 99.999% uptime). Downtime costs vary by scale but can run into thousands—or even tens of thousands—of dollars per minute for large operators. Beyond direct financial loss, an outage can disrupt critical services, cause SLA breaches, and reduce customer trust. Ensuring continuous, stable power involves integrated systems including utility feeds, UPS (uninterruptible power supplies), generator sets, and control/monitoring platforms. The challenge is not only to have backup power but to ensure it engages reliably and operates safely under varying load conditions. Shangchai (上柴) has established a reputation for producing robust and fuel-efficient diesel engines and generator sets. Key advantages of Shangchai equipment in data center contexts include: An intelligent control system acts as the brain of the backup power solution. Modern controllers provide functions beyond simple transfer switching: remote monitoring, predictive maintenance alerts, automatic synchronization, load sharing among multiple generator sets, and integration with building management systems (BMS). When employed correctly, these functions reduce operator workload, optimize fuel consumption, and increase overall system availability. Important features include: We tested a medium-sized data center configuration to evaluate the combined performance of a Shangchai G-series generator set and a contemporary intelligent control system. The primary objectives were: Test conditions simulated a full utility outage and included variable IT load profiles representing real-world usage peaks and troughs. Fast and reliable response: The controller initiated generator start-up immediately; the system reached stable output within 10–15 seconds, well within acceptable thresholds for most data centers when paired with a short UPS bridge. Voltage and frequency stability: With automatic governor and AVR (automatic voltage regulator) tuning, output variance stayed within ±2% during both transient and load-change events. Fuel efficiency gains: Intelligent load sharing and optimized warm-up procedures reduced diesel consumption by approximately 7–10% compared to baseline manual control. Predictive alerts and reduced downtime: The system’s telemetry flagged abnormal vibrational patterns and temperature drift before they caused measurable performance degradation. Overall, the integrated solution proved to be a practical and cost-effective option for improving backup power resilience in data centers of varying scale. When planning deployment, consider the following best practices: The integrated Shangchai + intelligent controller approach addresses many issues but also introduces considerations: Q1: How quickly can the Shangchai + intelligent control solution restore powered operations? A1: In our tests, the system achieved stable generator output within 10–15 seconds after a simulated grid failure. With a short UPS bridging window, data center operations experienced no interruption. Q2: Does the intelligent control system really save fuel? A2: Yes. Through optimized start-stop sequences, load sharing, and intelligent warm-up, we observed approximately 7–10% fuel savings compared to manual control strategies. Q3: Are Shangchai generators compatible with international control standards? A3: Shangchai generator sets typically offer standard electrical interfaces and can be configured to work with most modern controllers that support remote telemetry, ATS coordination, and CAN/Modbus communication protocols. Q4: What maintenance is required to keep the system reliable? A4: Routine maintenance includes scheduled oil and filter changes, fuel polishing, battery health checks, load-bank testing, and periodic firmware updates for controllers. Predictive alerts further reduce unexpected failures. Q5: Is the solution suitable for small data centers or edge sites? A5: Yes. The modular nature of generator sets and scalable controllers allows deployment across a range of site sizes—from small edge facilities to large hyperscale data centers. The future of data center power resilience will be hybrid and intelligent. Operators increasingly combine diesel gensets with battery energy storage systems (BESS), solar arrays, and automated microgrid controllers. Intelligent control platforms will orchestrate these assets to minimize cost, emissions, and risk while meeting strict uptime requirements. For exporters, marrying proven generator platforms like Shangchai with advanced controllers, secure communications, and local service capabilities will be a winning formula in global markets. The combined Shangchai + intelligent control system solution delivers a pragmatic, tested, and export-ready approach to data center power safety. Our measurements demonstrate rapid recovery, strong stability, and measurable fuel savings. As data center demand grows worldwide, particularly in emerging markets, this integrated approach provides a scalable and reliable means to protect critical infrastructure. Manufacturers and exporters should emphasize compatibility, after-sales service, and compliance with local standards when marketing these solutions internationally.2. Overview of the Shangchai generator platform

• Reliability: Marathon and continuous-duty rated engines designed to handle frequent starts and extended runtime.

• Compatibility: Available control interfaces and flexible electrical configurations that pair well with modern controllers.

• Cost-effectiveness: Competitive pricing that makes high-capacity backup more accessible for a wider range of facilities.3. Intelligent control systems: features and benefits

• Automatic Transfer Switch (ATS) coordination: Ensures smooth transition between grid and generator.

• Load-shedding and prioritization: Allows graceful degradation to protect critical infrastructure.

• Remote diagnostics and telemetry: Enables technicians to respond proactively and reduces mean time to repair (MTTR).

4. Test setup: methodology and objectives

• Measure response time from grid failure to stable generator supply;

• Evaluate voltage and frequency stability during transient and steady-state conditions;

• Assess fuel consumption and efficiency under intelligent load management;

• Validate remote monitoring and alarm workflows.5. Test results: key findings

6. Practical considerations for deployment

• Right-size generator capacity: Oversizing increases fuel use; undersizing risks overload. Model the peak and critical loads carefully.

• UPS bridging: Ensure UPS systems can cover the generator start interval to avoid interruptions.

• Regular testing and maintenance: Scheduled load-bank tests and exercising of the ATS and generator sets prevent start-failures.

• Cybersecurity for control systems: Implement secure network segmentation, firmware validation, and role-based access to protect controllers from attacks.7. Challenges and mitigation strategies

• Emissions and regulations: Ensure compliance with local emission standards and consider selective catalytic reduction (SCR) and particulate filters where required.

• Fuel quality and logistics: Poor fuel quality can degrade engine life; plan for proper storage and filtration.

• Skilled operations: Training for local technicians on advanced controller features and remote diagnostics is essential.8. Frequently Asked Questions (Q&A)

9. Industry trends and the path forward

Conclusion

Hot products

+86 15244567972

Contacts:Jack