How to Extend Generator Set Lifespan Maintenance Tips and Recommended Service Intervals

Release time:2025-09-11 Click:20

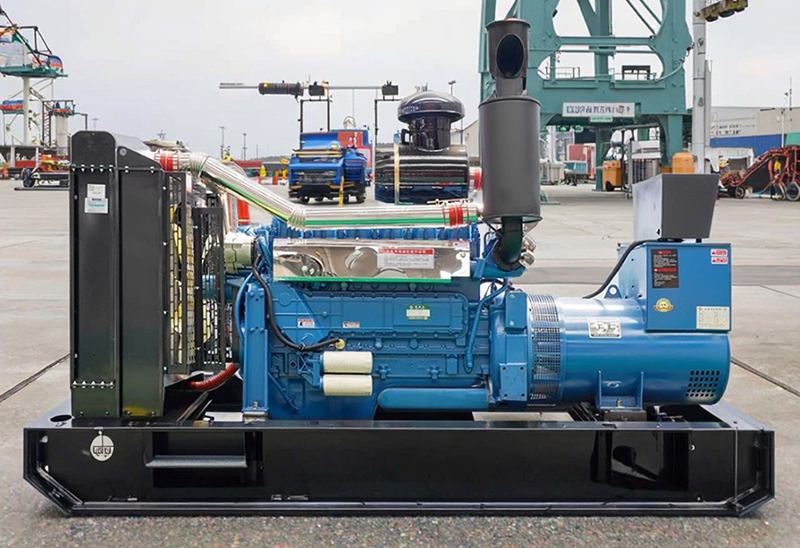

As a global supplier of power solutions, we’ve seen firsthand how regular maintenance directly affects generator set performance and longevity. A well-maintained generator not only saves money on repairs but also ensures reliable power during critical operations. This article will explore the key practices to extend the life of your generator sets, whether diesel or gas-powered, and provide a clear schedule of maintenance intervals.

Generator sets are long-term investments. Without proper care, wear and tear accelerates, resulting in higher fuel consumption, reduced efficiency, and unplanned downtime. In industries like construction, hospitals, or data centers, an unexpected outage can be extremely costly. Routine maintenance extends the operational life of your equipment and protects your investment.

a. Regular Oil and Filter Changes Engine oil degrades over time due to heat and contaminants. Changing oil and filters at recommended intervals (often every 250–500 operating hours for diesel units) ensures proper lubrication and prevents engine wear.

b. Cooling System Care Check coolant levels regularly and flush the system as recommended by the manufacturer. Overheating is one of the leading causes of generator damage.

c. Battery Inspection A generator is only as reliable as its starting system. Inspect and test batteries monthly, clean terminals, and ensure chargers are functioning.

d. Fuel System Maintenance Contaminated fuel leads to clogged filters and injector damage. Drain water from fuel tanks periodically and use additives if necessary to prevent microbial growth.

e. Air Filter Replacement Dust and debris can choke your engine. Replace air filters as soon as they’re dirty or clogged to maintain efficient combustion.

f. Keep It Clean and Dry Regularly clean the generator’s exterior and housing. Moisture and dust buildup can cause electrical faults and corrosion.

Visual inspection: Weekly Battery test & cleaning: Monthly Oil & filter change: 250–500 hrs of operation Fuel filter replacement: 500 hrs or annually Coolant flush: Every 12 months Full load test: Every 6 months Professional inspection: Annually

If your generator is used seasonally or stored for extended periods, run it under load at least once a month to circulate oil and fuel. This prevents seals from drying and reduces startup issues later.

While basic inspections can be done by your staff, complex maintenance such as valve adjustments or load bank testing should be performed by certified technicians. A hybrid approach—simple daily checks plus scheduled professional servicing—offers the best results.

Q1 How often should I run my standby generator to keep it in good condition?

A: At least 30 minutes under load once a month. This keeps components lubricated and identifies potential problems early.

Q2 Can I use automotive oil in my generator’s engine?

A: Not recommended. Always use oil types and grades specified by the generator manufacturer for best performance and warranty compliance.

Q3 What are the signs my generator needs immediate service?

A: Unusual noises, increased fuel consumption, frequent starting issues, or low output voltage are red flags.

Q4 How can I prevent fuel contamination?

A: Keep tanks sealed, drain water periodically, and use fuel stabilizers if storage exceeds three months.

Q5 Does load testing really matter?

A: Yes. Load testing reveals whether your generator can handle actual demand and prevents “wet stacking” in diesel engines.

Modern generators come equipped with telematics and monitoring systems. Use these to track run hours, fuel consumption, and error codes. Maintaining digital logs helps schedule maintenance more accurately and provides documentation for warranty claims.

Skipping scheduled service to “save money” (it costs more later). Using poor-quality fuel or counterfeit filters. Ignoring small leaks or unusual vibrations. Overloading the generator beyond rated capacity.

As a Chinese manufacturer exporting generator sets worldwide, we not only supply high-quality units but also provide training, spare parts, and maintenance support. This holistic approach ensures our customers enjoy a full lifecycle of reliable performance from their power equipment.

Extending the lifespan of your generator set is not complicated but requires discipline and planning. By following manufacturer guidelines, implementing a structured maintenance schedule, and working with a trusted supplier, you can achieve significant savings, reduce downtime, and ensure consistent power supply.

Hot products

+86 15244567972

Contacts:Jack