Southeast Asia Dealers Show: How Cummins Generator Sets Power Construction Sites Around the Clock

Release time:2025-09-06 Click:20

Power reliability is the lifeblood of modern construction projects. Across Southeast Asia, where rapid urbanization and infrastructure investment are reshaping skylines and road networks, uninterrupted electricity is not optional — it is essential. This article compiles dealer footage, firsthand feedback, technical insights, and practical tips to explain why Cummins generator sets supplied via Chinese exporters are a top choice for contractors who demand continuous, dependable on-site power.

1. Southeast Asia’s Rising Demand for Reliable Power

Cities and infrastructure projects in Indonesia, Vietnam, the Philippines, Thailand, and Malaysia are expanding at pace. Many construction sites operate in peri-urban or remote zones where utility grids are intermittent or nonexistent. In this context, contractors rely on robust generator sets to keep cranes, concrete pumps, welding equipment, lighting, and temporary offices running without interruption. Dealers on the ground report increasing orders for units designed specifically for heavy-duty, around-the-clock operation.

Cummins has a global reputation for reliable diesel engines, and that reliability translates into generator sets that perform consistently under load. Dealers frequently cite the following strengths: proven durability under harsh conditions, fuel-efficient engine designs that reduce operating cost, low emissions that help projects comply with environmental rules, and straightforward maintenance that reduces downtime.

For construction contractors, these attributes mean fewer interruptions, lower life-cycle costs, and simpler logistics. Chinese suppliers who partner with Cummins or supply compatible generator sets can offer competitive pricing, fast delivery, and localized support—advantages that resonate strongly in price-sensitive yet quality-aware Southeast Asian markets.

Several dealers in the region provided video clips and site reports demonstrating real use cases. In Ho Chi Minh City, a distributor showcased a Cummins-powered set keeping a high-rise project powered through repeated city brownouts. Engineers noted steady voltage and minimal fluctuation while multiple pumps and welding rigs ran simultaneously. In Jakarta, a mobile unit was filmed supplying a large roadworks crew operating 24 hours a day — crews reported zero unplanned stoppages attributable to power loss during a month-long period.

These testimonials are convincing for overseas buyers: they show how properly specified units deliver measurable uptime improvements and reduce the operational stress of managing power on complex, multi-shift sites.

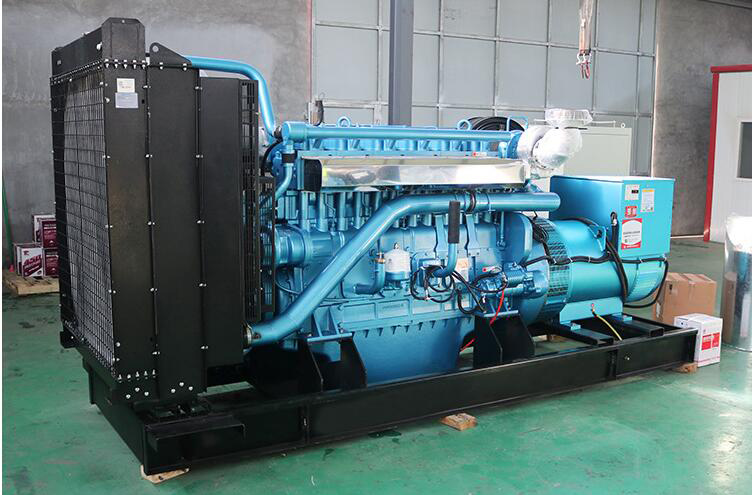

Modern Cummins generator sets integrate a range of features aimed at heavy-duty applications: automatic load management to handle fluctuating demands, sound-attenuated enclosures for urban noise control, integrated digital controllers with remote monitoring for quick diagnostics, and parallel-ready configurations allowing multiple units to run together for redundancy or larger capacity. These features reduce onsite management complexity and improve both safety and efficiency.

Fuel is one of the largest ongoing costs for generator operation. Cummins’ engine designs focus on fuel economy without sacrificing power output, which leads to lower operational expenses over the life of the unit. Meanwhile, emissions controls and after-treatment systems help construction firms meet local environmental guidelines, an increasingly important factor as governments tighten air quality and noise regulations around urban projects.

Q1: Are Cummins generator sets suitable for the hot and humid climates of Southeast Asia?

A1: Yes. Cummins sets intended for tropical deployment include enhanced cooling systems, corrosion-resistant components, and air filtration suited for dusty or coastal sites. When specified correctly for the environment, they handle humidity and high ambient temperatures reliably.

Q2: How long can a Cummins generator run continuously on a construction site?

A2: With proper maintenance, fuel management, and scheduled service intervals, these generator sets are designed for extended operation, including continuous 24/7 use. Best practice includes routine inspections, filter changes, and oil analysis to prevent unexpected failures.

Q3: What sizes and configurations are commonly used on large construction projects?

A3: Units range from portable 20–80 kVA sets for small sites and temporary offices, up to several hundred kVA or multi-megawatt paralleled installations for major developments. Contractors often use a mix of mobile and stationary units to cover different power needs across a single job site.

Q4: How easy is it to get spare parts and service in Southeast Asia?

A4: Many Chinese exporters coordinate with local dealers to stock spare parts and provide technical training. Cummins’ global network and commonality of parts make it relatively straightforward to source consumables and critical components when needed.

Q5: Can these generator sets be supplied with certifications needed for local compliance?

A5: Yes. Suppliers can provide compliance documentation, emissions certificates, and safety documentation to meet the regulatory requirements of most Southeast Asian countries. It’s important to confirm the exact paperwork required for the destination country before shipping.

For Chinese manufacturers and trading companies, the construction boom in Southeast Asia represents a robust export opportunity. Success depends on reliable logistics, transparent lead times, and clear after-sales arrangements. Many exporters bundle installation, commissioning, and operator training into turnkey offers that simplify procurement for foreign contractors and reduce project risk.

Top-performing dealers in the region offer more than machines: they provide fuel planning, preventative maintenance contracts, remote monitoring services, and rapid-response teams during critical project phases. These value-added services convert a one-time sale into a long-term partnership and are often the deciding factor for contractors choosing a supplier.

A major contractor in Metro Manila installed two parallel Cummins generator sets imported through a Chinese trading partner. The paralleled configuration provided redundancy and balanced loading, which reduced individual engine stress and improved fuel use. Over the span of a year, the contractor recorded lower maintenance incidents and an estimated 20% reduction in fuel consumption versus their legacy setup.

Buyers should evaluate total cost of ownership (TCO) rather than purchase price alone. TCO includes fuel consumption, maintenance, downtime costs, and parts availability. Cummins’ fuel-efficient designs and proven durability frequently yield lower TCO on long projects despite a moderate initial investment. Partnering with exporters who provide clear maintenance schedules and parts support further reduces lifecycle expense.

The future of construction site power blends diesel generator reliability with smart control systems and battery-hybrid solutions. IoT-enabled monitoring enables predictive maintenance and fuel optimization, while hybrid configurations reduce fuel use and emissions during low-load periods. Chinese suppliers are already preparing to offer such integrated solutions to meet evolving contractor demands.

Dealer footage and on-site feedback from across Southeast Asia underscore one clear message: dependable generator sets are essential to modern construction success. Cummins-powered units, when supplied with robust after-sales support and correct site specification, deliver the uptime, efficiency, and compliance contractors need. For Chinese exporters, offering reliable equipment combined with logistics, documentation, and local dealer partnerships is the formula for long-term success in these dynamic markets.

By focusing on quality, transparent service, and proactive support, exporters can help contractors meet deadlines, control costs, and build the infrastructure that underpins regional growth. If you are evaluating power solutions for large-scale projects, consider total lifecycle support and local dealer capabilities as primary factors alongside machine specifications.

Hot products

+86 15244567972

Contacts:Jack